Bicarbonate Analyzer

The Importance Of Bicarbonate Monitoring

Bacteria in anaerobic digesters require a pH-value in the range of about 6.5 to 8 to efficiently produce biogas. Stabilization of the pH-value within this range is predominantly obtained (> 85%) by the release of large amounts of bicarbonate (a buffering compound) from the anaerobic decomposition of organic wastes.

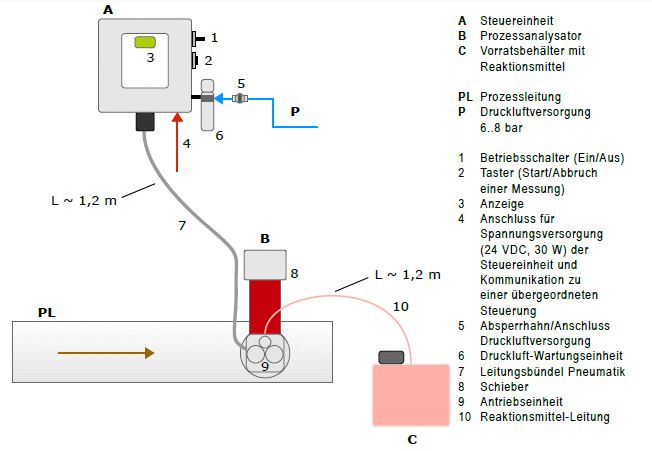

Image shows THE FITEC DIGESTER HEALTH MONITOR

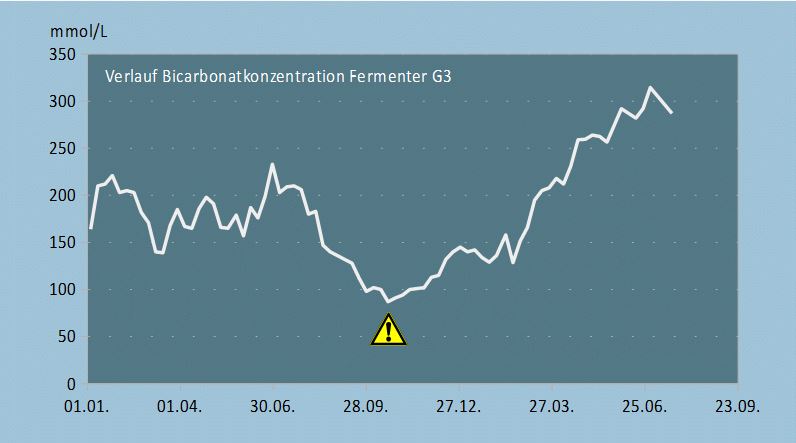

Process interruptions, such as overfeeding, often result in increased concentrations of volatile fatty acids (VFA) and to decreasing amounts of bicarbonate as these acids consume the bicarbonate.

If these interruptions continue, the supply of bicarbonate will become depleted leading to a rapid decrease in the pH-value and subsequently a reduction biogas production and in extreme cases, complete biological collapse leading to plant failure.

Advantages Of Process Control With a Bicarbonate Analyzer

◆ With fully automatic monitoring of a plants bicarbonate levels the APAS monitor will detects changes earlier than other tools available.

◆ Rapid results gives an operator the time needed to avoid economic losses.

◆ The large amount of generated data by fully automatic monitoring enables a close relationship to the existing operating conditions inside a digester. Determining what causes dips in biogas production becomes significantly easier.

◆ The automated measurement feature enables 24/7 remote monitoring of the biological system.

◆ The APAS testing method increases the availability of biogas plants and thus their financial success.